Last week I spent some time talking about ironing or pressing laminate especially as it applies to attaching a fusible fleece or interfacing. In case you missed it you can read it here. After that post, I continued working with the laminate and found the Teflon sheets were just a little bit smaller than my project. I had an AH-HA moment. I ran (ok I didn’t run, but I walked quickly) into the kitchen and got out my parchment paper.

Sure enough, I had two different brands of parchment paper. For those of you that haven’t used it for cooking, it is a nice crisp paper that is non-stick and can be used to line a baking sheet when cooking a variety of things but I use it primarily for cookies. Although it’s typically white or natural it is sheer enough to be able to see a line drawing through it. Many people us it for appliqué.

OK so back to ironing. The paper worked perfect and in fact I liked it a lot better than the Teflon pressing sheets. One of these packages has now moved from the kitchen to my sewing room.

Now it was time to sew. Typically when we sew, we put right sides together so that the wrong side of the fabric is a against our pressure foot and the bed of the sewing machines. As long as that is how you are sewing the laminate, no problem, it’s just like sewing any cotton fabric (remember the laminate is only on the right side of the fabric). I used an 80/10 topstitch needle because that’s what I usually have in my machine. I think whatever needle you typically use will work just fine. BTW the laminate doesn’t seem to show pin marks. I was able to pin the layers together without seeing anything. I even had to do a little reverse sewing and the laminate looked just fine.

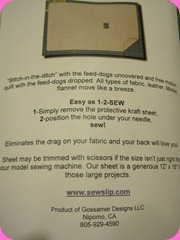

Everything was going along well until it was time to topstitch. The bag that I made has pockets topstitched in place as well as some other topstitching that means I now had to deal with the laminate riding against the sewing machine bed as well as the pressure foot. Here’s what I did to make the job much easier.

First, a Teflon pressure foot. Although I have a Bernina, I believe most of the major manufactures make either a Teflon foot or a rolling foot to handle sewing on difficult fabrics. Check with your dealer.

That’s it, other then when you need to sew with the laminate touching the foot or bed it’s business as usual. Give it a try, it’s worth the little bit of extra work.

Enjoy,

I have never thought of using the SewSlip for that purpose, but it is a great idea. It's amazing how many kitchen tools end up in my sewing studio!!

ReplyDeleteVery interesting. I don't have a teflon foot for my Bernina. Had actually been wondering why I might want one, but now I see times when I've sewn that it probably would have helped. I'm definitely going to track it down and get one.

ReplyDeleteGreat post. Thanks.

SewCalGal

www.sewcalgal.blogspot.com